Tandem Mold

DIVER MOLD / PRODUCTS / TANDEM MOLD

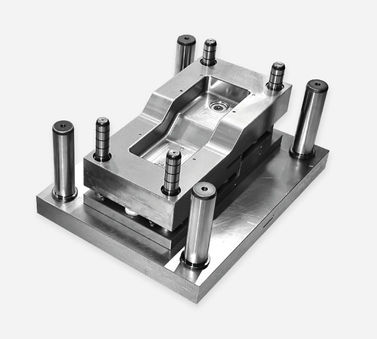

Tandem Mold

Tandem molds offered by the Dalgıç Kalıp brand are an effective solution that has an important place in the industry and is used in the production of large-scale parts. It is a preferred option in the sector thanks to its high precision and efficient production processes. Dalgıç Kalıp stands out with its Tandem molds to meet the sectoral needs with its customer-oriented service approach.

High Precision: Tandem molds are special mold systems that provide high efficiency in the metal forming process. These systems, which include multiple molding stations, increase productivity by enabling the production of multiple parts at the same time.

Precision Machining: Tandem molds have technical features that enable precision machining of parts. Designed using advanced technology, these molds perform the shaping and dimensioning of parts with high precision.

Multiple Stations: Tandem molds have a complex structure that accommodates more than one station. Each station is customized to perform a different operation. In this way, it is ensured that the parts are completed by sequential operations.

Wide Application Area: Tandem molds have a wide range of applications in the metal industry. Tandem molds, which are widely used in industries such as automotive, white goods and construction, are effectively used in the production of different parts and components.

What is Tandem Mold and Its Importance in Industries

As Dalgıç Kalıp, tandem mold production is among the quality solutions we offer in the field of metal forming. Tandem molds are special mold systems that play an important role in the metal industry. In this article, we will discuss in detail what tandem molds are, their use in the automotive, white goods and electronics industries and their technical features.

Use of Tandem Molds in Automotive, White Goods and Electronics Industry

Tandem molds have a wide range of uses in the automotive, white goods and electronics industries. In the automotive industry, vehicle bodies, chassis components, door panels and many other parts are produced using tandem molds. In the white goods sector, these molds are used in the production of products such as refrigerators, ovens, washing machines. In the electronics industry, tandem molds are also used effectively in the production of sensitive electronic components and devices. The use of tandem molds in these industries plays an important role in meeting high standards of precision, efficiency and quality.

Tandem Mold Production and Technical Features

As Dalgıç Kalıp, we offer customized tandem mold solutions to our customers. Tandem molds have a complex structure that accommodates more than one station. Each station is designed to perform a different operation and comes together to obtain the finished product. Tandem mold production is a process that requires high precision, durability and efficiency. As Dalgıç Kalıp, we offer tandem mold solutions suitable for the needs of our customers with our technological infrastructure and experienced team.